Becker Mewis Duct®Twisted

The Becker Mewis Duct® (BMD) has proved to be very successful for large and slow speed ships like bulkers and tankers. Instead, the Becker Mewis Duct® Twisted (BMDT), formerly known as Becker Twisted Fin (BTF), was developed for faster ships as container vessels.

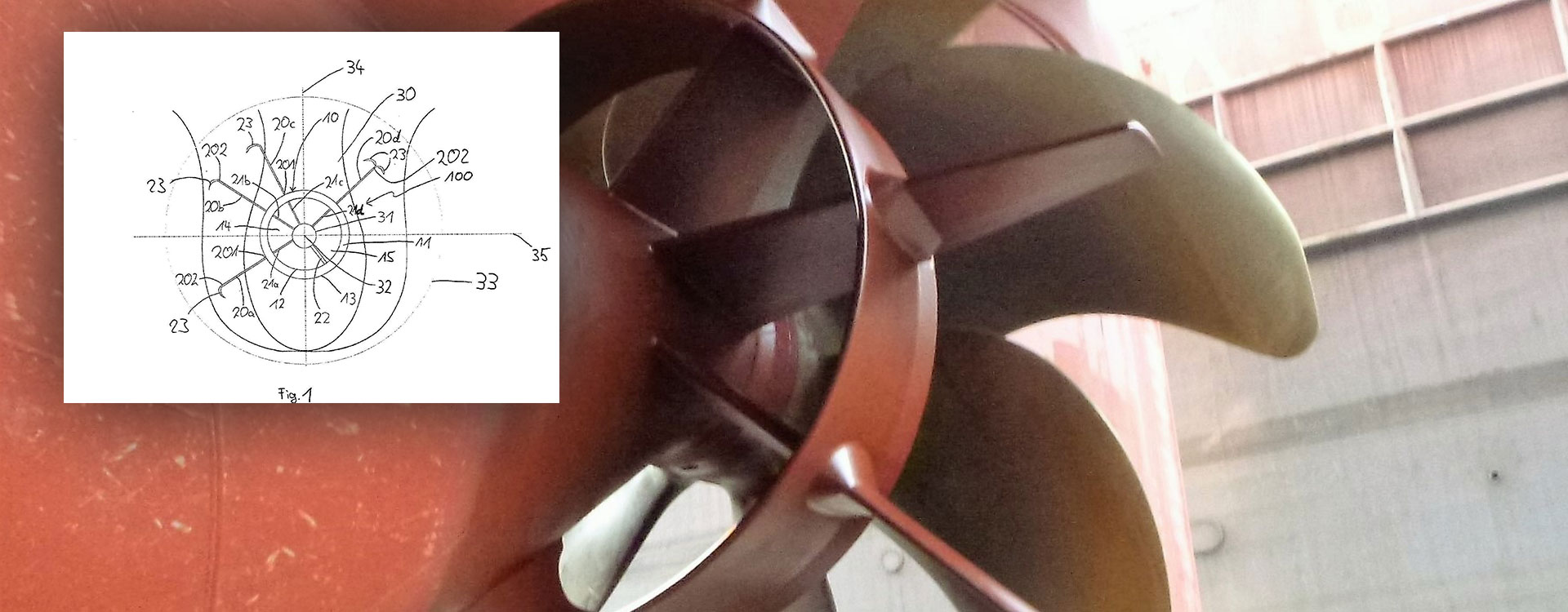

Like the BMD, the Becker Mewis Duct® Twisted has no movable parts, is also installed in front of the propeller and generates a pre-swirl. The nozzle ring is significantly smaller than that of the BMD and has specially-developed thinner profiles which significantly reduce drag. The fins familiar from the BMD on the inside of the nozzle ring or sectional ring extend outwards beyond the nozzle. The fins are both tapered and twisted with modifications to the free outer fin tips. The cavitation risk has been minimised by these measures.

Computational Fluid Dynamics (CFD) calculations and model tests after more than 50 test series have shown fuel savings averaging about 3.4 % for container ships.

For more information see the publication No 54.

Short history:

- September 2012: patent pending

- October 2012: first model test

- December 2012: first installation in fullscale

- November 2015: the 50th BMDT has been sold

- June 2021: the 200th BMDT has been sold

Becker Marine Systems in Hamburg is marketing and selling the Becker Mewis Duct® Twisted exclusively.

Becker Mewis Duct® Twisted in full scale

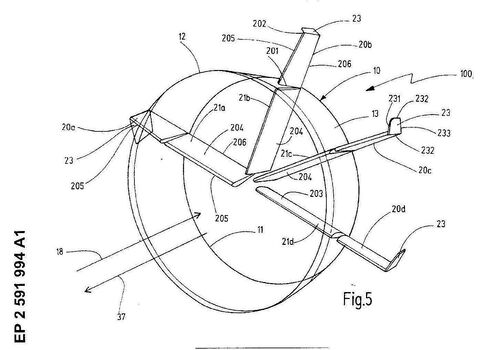

Sketch of patent, 2012